Productivity in Management – FAQs and Key Concept

- Other Laws|Blog|

- 11 Min Read

- By Taxmann

- |

- Last Updated on 25 October, 2025

Productivity in Management refers to the efficient and effective use of resources—such as manpower, materials, money, and machinery—to achieve organisational goals. It measures the relationship between inputs and outputs, i.e., how much output (goods or services) is produced per unit of input. In simpler terms, productivity indicates how well management utilises resources to produce maximum results with minimum effort, cost, or waste.

Table of Contents

- Introduction

- Quality Certification

- Quality System

- Guidelines for Use

- Frequently Asked Questions (FAQs)

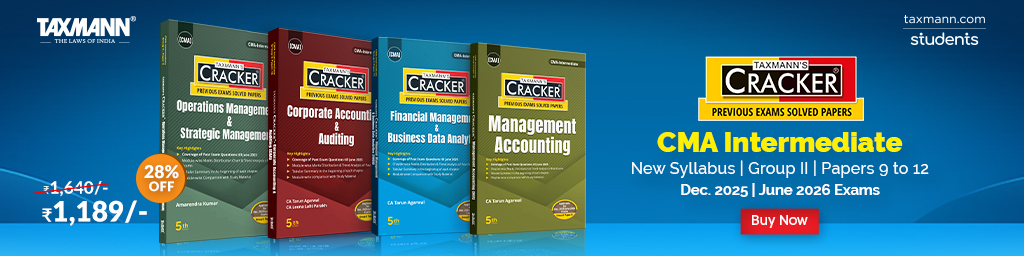

Check out Taxmann's Operations Management & Strategic Management (OMSM) | CRACKER which features an extensive collection of past exam questions, including module-wise solved papers from June 2025, complemented by additional practice questions and detailed answers for enhanced learning. The key features include tabular summaries for quick reference, comprehensive marks distribution analysis since June 2023, and exam trend analysis up to December 2023. Additionally, the guide offers module-wise comparisons with ICMAI study materials and thoroughly covers essential topics in Operations Management and Strategic Management, ensuring candidates are thoroughly prepared for the examinations. CMA Intermediate | New Syllabus | Dec. 2025/June 2026 Exams

1. Introduction

The I.L.O. publication, “Higher Productivity in Manufacturing Industries” has defined productivity as the ratio between output of wealth and the input of resources used in the process of production.

The European Productivity Agency (EPA) has defined productivity as follows:

“Productivity is an attitude of mind. It is a mentality of progress of the constant improvement of that which exists. It is the certainty of being able to do better today than yesterday, and continuously. It is the constant adaptation of economic and social life to changing conditions, it is a condition, it is a continual effort to apply new techniques and methods, it is the faith in human progress.”

The term productivity can be defined in two ways. In simple terms, productivity is defined as a ratio between the output and input – between what is produced and what is required to produce it. A continual effort to apply new techniques and methods is the faith in human progress.

![]()

In a broader sense, productivity is defined as a measure of how well resources are brought together in organisations and utilised for accomplishing a set of results.

The importance of the concept of productivity can be viewed from the following points:

1. To beat the competition – It is an age of cut-throat competition. There may be other commodities which can serve as the substitutes of the terms ‘product’ and can attract the consumers’ purchasing power. The firm whose productivity is higher can only beat the competition and can exist in the market for long.

2. Guide to Management – The productivity indices are very useful for the management and can be used for different purposes. These indices can serve as a valuable guide to the management for improving the performance of its enterprise. The productivity measures can be used for the following purposes:

(a) Strategic – With the help of productivity indices, the efficiency of different firms can be measured, analysed and compared. The necessary steps can be taken to improve the productiveness of the firm taking in view the productiveness of the other competitive firms.

(b) Tactical – Different units or the sectors of the firm can also be compared as regards to their productivity and the productivity of the less productive units or sectors can be improved.

(c) Planning – A firm uses different inputs in producing the goods. A comparison of relative benefits accruing from the use of different inputs can be had and the most beneficial input can be used in production. It helps the management to plan for the future.

(d) Administration – Productivity indices indicate the progress of the firm over a period of years. The productivity of different inputs, including labour, can be measured individually. The individual productivity indices help the management in bargaining with the labour leaders, trade unions and the Government in case of labour disputes regarding welfare activities. Thus administration can be improved with the help of productivity indices.

3. An Indicator of Progress – In economically backward countries, productivity movement is basic aspect of progress. It implies the development of an attitude of mind and a constant urge to better, cheaper, quicker and safer ways of doing a job, manufacturing a product and providing a service. In an urge to improve the productivity, new inventions take place. This productivity is an aspect of basic progress.

4. Maximum utilisation of Scarce Resources – In order to provide the articles or commodities to the consumers at the lowest possible cost, the productivity urges to utilise the available resources to the maximum to the satisfaction of customers. The productivity processes and techniques are designed to facilitate more efficient work involving less fatigue to workers by improvements in the layout of the plant and work, better working environment and simplification of works.

5. Key to National Prosperity – The productivity, in fact, has become the synonymous to progress. Higher productivity is an index of more production with the same inputs at lower cost. It enables industry to offer goods to the general public at cheaper rates and results in expansion of markets. The working conditions and wages of workers will improve and industrialists too will get larger profits. Thus higher productivity is the key to national prosperity. The secrets of Japan and Western countries’ prosperity lie in increased productivity.

6. Prosperity to Labour – The higher productivity is a boon to labour also. It brings improved working conditions, better wages and salaries to workers, better labour welfare activities to labourers. Thus their standard of living is improved.

2. Quality Certification

Many international businesses recognise the importance of quality certification. The EU, in 1987, established ISO [International Organisation for Standardisation] 9000 certification.

Two of the most well known of these are ISO 9000 and ISO 14,000.

ISO 9000 pertains to quality management. It concerns what an organisation does to ensure that its products or services are suitable to customers expectations.

ISO 14,000 concerns minimisation of harmful effects to the environment caused by its operations.

Both ISO 9000 and ISO 14000 are related to an organisation processes rather than its products and services and they stress continual improvement.

ISO 9000 is composed of the national standard bodies of 91 countries. About

90 countries have adopted ISO 9000 as national standards.

This certification is intended to promote the idea of quality at every level in the organisation.

ISO certification is an elaborate and expensive process. Any firm seeking this certification needs to document how its workers perform every function that affects quality and install mechanisms to ensure that, they follow on expected lines.

ISO 9000 certification entails a complex analysis of management systems and procedures. Rather than judging the quality of a particular product.

ISO 9000 evaluates the management of the entire manufacturing process, from purchasing, to design to training. A firm that seeks this certification must fill out a report and then be certified by a team of independent auditors.

With certification comes registration in an ISO directory, that firms seeking suppliers can refer to, for a list of certified companies. They are generally given preference over unregistered companies.

There are essentially five standards associated with the ISO 9000 series. The series, if we place them on a continuum, would range from design and development through procurement, production, installation and servicing. Whereas, ISO 900X3 and 9004 only establish guidelines for operation, ISO 9001, 9002 and 9003 are well-defined standards.

3. Quality System

9001 Model for Quality Assurance in Design, Production, Installation and Servicing. (To be used when conformance to specified requirements is to be assured by the supplier during several stages that may include design/development, production, installation and servicing).

9002 Model for Quality Assurance in Production and Installation. (To be used when conformance to specified requirements is to be assured by the supplier during production and installation). 9003 Model for Quality Assurance in Final Inspection Test. (To be used when conformance to specified requirements is to be assured by the supplier solely at final inspection and test).

4. Guidelines for Use

9000 Quality Management and Quality Assurance Standards – Guidelines for Selection and Use.

9004 Quality Management and Quality System Elements – Guidelines.

ISO 9000 Standards, their Areas of Application in Production Flow and Guidelines for Use

5. Frequently Asked Questions (FAQs)

FAQ 1. What are the Principles of Total Quality?

- Quality oriented management

- Focus on customer

- Involving (entire) workforce

- Continuous improvement

- Supplier Partnership

- Measuring performance

FAQ 2. What are the advantages of the KAIZEN Technique?

Kaizen is focused on making small improvements on a continuous basis.

In simple terms Kaizen is Japanese for ‘a change for better’, which results in ‘continuous improvement’.

The advantages of KAIZEN are as follows:

- Kaizen involves every employee in process of change mostly in small, incremental changes. It focuses on identifying problems at their own source, solving them at their own source, and changing standards to ensure the problem stays solved forever.

- By involving employees they start looking about change at their environment to bring up results in their work area and improved morale as employee begins to find work more enjoyable and easier.

- Kaizen reduces waste in area such as employee skills, waiting time, transportation, worker motion, over production, excess in inventory, quality and process.

- Kaizen improves product quality, use of capital, production capacity, communications, space utilisation and employee retention.

- Incorporation of visual action oriented tasks.

FAQ 3. What are the three models of Productivity Measurement?

The models of Productivity Measurement can be classified into three on the basis of the type and coverage of the output and input variables:

- Ratio method

- Production Function method

- P-O-P method.

FAQ 4. What are the three levels of quality?

Three levels of Quality:

- Organisation level – Satisfying requirements of external customers.

- Process level – Meeting the needs of internal customers.

- Performer level (job level or task design level) – Meeting and maintaining the requirements of accuracy, completeness innovation, timeliness and cost.

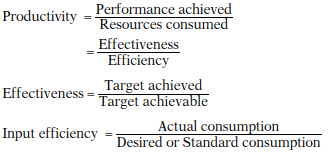

FAQ 5. What is the formula for Input Efficiency and Effectiveness?

Input efficiency = Actual consumption/Desired or standard consumptionEffectiveness = Target achieved/Target achievable.

FAQ 6. What are the Eight Most Common Benchmarking Errors?

The Eight Most Common Benchmarking Errors:

- Lack of Self-Knowledge – Unless own operations are thoroughly analysed, the benchmarking efforts will not pay off. One has to know how things work in a company, how effective current processes are, and what factors are critical. That’s why internal benchmarking is an important first step.

- Benchmarking everything – Be selective. Benchmarking another company’s employee food service will usually not be worth the time, energy, and cost. Own TQM effort as a whole will point out the areas where benchmarking is most likely to pay off.

- Benchmarking projects are broad instead of being focused – The more specific the project, the easier it is and the more likely it will generate useful ideas. Benchmark a successful company’s hiring procedures, not their entire human resources operations. Focus on accounts receivable handling, not the accounting department as a whole.

- Benchmarking produces reports, not action – Studies have indicated that 50% of benchmarking projects result in no specific changes. The process is not an academic exercise. It should be geared toward generating and implementing actual changes.

- Benchmarking is not continuous – Benchmarking is a process. Even before one reaches the benchmark one has set, one should take another look at partner’s performance, or at other companies. New goals should be established and new techniques adopted. The process never ends.

- Looking at the numbers, not the issues – While the measures are important, they are not the heart of the process. At some companies, benchmarking is used to set goals, but not to generate the important changes needed to meet them.

- Participants are not motivated – Make sure benchmarking team members have the time to do the job. Even if the project is simply added on their regular jobs, make sure each has a stake in the success of the project. Benchmarking should not be considered as “busy work” to be assigned to a group of low-level employees.

FAQ 7. What are the different approaches to overcoming hurdles in the management of productivity improvements?

The different approaches to overcome hurdles in the management of productivity improvements are as follows:

- Management by internal motivation (i.e., KAIZEN)

- Management by incentives

- Management by fear

FAQ 8. What is TQC and what are its principles?

TQC is Total Quality Control. It is quality control and improvement from shop floors to board rooms. It is an effective system for integrating quality development, quality maintenance and quality improvement efforts of various groups in an organisation.

Principles of Total Quality Control (TQC)

- Top management policies-Zero defects, continuous improvement etc.

- Quality control training for everyone.

- Quality at product/service design stage.

- Quality materials from suppliers.

- Quality control in production (SQC).

- Quality control in distribution, installation and usage.

FAQ 9. Define the following terms with reference to measuring productivity:

(a) Validity

(b) Completeness

(c) Compatibility

(d) Inclusiveness

(e) Timeliness

(f) Cost effectiveness

(g) Partial productivity

Measuring Productivity:

Bain suggests that a good productivity measure should possess the following properties. The more closely the measurement meets these criteria, the more useful it is for improving productivity.

(a) Validity – It reflects accurately the changes in productivity.

(b) Completeness – It takes into consideration all components of both the output and the input for a given productivity ratio.

(c) Compatibility – It enables the accurate measurement of a productivity change between periods.

(d) Inclusiveness – It takes into account and measures separately the productivity of all activities.

(e) Timeliness – It ensures that data is provided soon enough for managerial action to be taken when problems arise.

(f) Cost effectiveness – It ensures that data is provided soon enough for managerial action to be taken when problems arise.

(g) Partial Productivity – This measures productivity of one factor or input, keeping other factors or inputs constant or unchanged.

FAQ 10. What is Quality Triology under Total Quality Management?

Quality Triology – Under Total Quality Management quality takes a holistic approach to quality and his concept of quality revolves around what is called a quality trilogy, which is composed of:

- Quality planning,

- Quality control, and

- Quality improvement.

FAQ 11. “Higher productivity has manifold advantages.” What are these advantages?

Higher productivity has manifold advantages:

To the Individual Concern:

(a) Higher productivity means more wages directly to the piece-workers and more production bonus to all workers. It means satisfied staff and harmonious staff relations.

(b) The factory earns more profit because of the reduction in costs.

(c) Continuous higher productivity may induce the management to reduce selling prices so that sales and production may increase.

To the Industry – Higher productivity in some concerns will enable less efficient firms to follow them for their own survival.

To the Government:

(a) Higher profits earned by factories will bring more revenue to the government by taxation.

(b) Export trades may develop bringing more foreign exchange to the nation.

(c) Overall higher productivity will raise the all-round standard of labour.

FAQ 12. What is the ‘Eight Steps Benchmarking Process’?

Eight Steps Benchmarking Process:

- Select Benchmarking subject and appropriate team

- Identify performance indicators and Drivers

- Select Benchmark partners

- Determine data collection method and collect data

- Analyse performance gaps.

- Communicate Findings and identify projects to close gaps

- Implement plans and monitor results

- Recalibrate benchmarks.

FAQ 13. What is the formula for Input Efficiency?

Input Efficiency = Actual consumption/Desired or standard consumption Effectiveness = Target achieved/Target achievable.

FAQ 14. What are the benefits of Benchmarking?

Benefits of Benchmarking:

- Benchmarking is particularly helpful in validating proposals for change.

- Benchmarking often results in creative imitation and the adoption of new practices that overcome previous industry barriers.

- This search for diversity and for innovative breakthroughs, applied elsewhere is at the core of benchmarking benefits.

- By sharing information, all parties benefits, because it is difficult to excel in all activities.

- Sharing information and data is often first hurdle to be overcome in the Benchmarking process.

- Do not, however, attempt benchmarking in areas in which trade secrets or sensitive information determines the outcome of the process.

- Benchmarking, used in conjunction with other quality techniques or used alone, can influence how an organisation operates.

- If the search for “Best”, or just “Better” practices is performed correctly, then the likelihood of successful outcomes is quite high.

FAQ 15. What are the causes of low productivity in the Indian context?

In the Indian context, the causes of low productivity have their origin in two distinct sources.

- The first category consists of the exogenous or external factors like shortages of essential inputs-power, raw materials, transport facilities etc. over which the management of an enterprise has little or no control.

- The second basket contains the endogenous or internal factors mainly in the form of system deficiencies preventing the optimum utilisation of resources.

FAQ 16. What are the objectives of Quality Control and also Quality requirements from the customer’s point of view?

Objectives of quality control are to provide products/services which are dependable, satisfactory and economical.

Quality requirements from customer point of view:

- Conformance to specifications (requirements).

- Value for money

Disclaimer: The content/information published on the website is only for general information of the user and shall not be construed as legal advice. While the Taxmann has exercised reasonable efforts to ensure the veracity of information/content published, Taxmann shall be under no liability in any manner whatsoever for incorrect information, if any.

Taxmann Publications has a dedicated in-house Research & Editorial Team. This team consists of a team of Chartered Accountants, Company Secretaries, and Lawyers. This team works under the guidance and supervision of editor-in-chief Mr Rakesh Bhargava.

The Research and Editorial Team is responsible for developing reliable and accurate content for the readers. The team follows the six-sigma approach to achieve the benchmark of zero error in its publications and research platforms. The team ensures that the following publication guidelines are thoroughly followed while developing the content:

- The statutory material is obtained only from the authorized and reliable sources

- All the latest developments in the judicial and legislative fields are covered

- Prepare the analytical write-ups on current, controversial, and important issues to help the readers to understand the concept and its implications

- Every content published by Taxmann is complete, accurate and lucid

- All evidence-based statements are supported with proper reference to Section, Circular No., Notification No. or citations

- The golden rules of grammar, style and consistency are thoroughly followed

- Font and size that’s easy to read and remain consistent across all imprint and digital publications are applied

CA | CS | CMA

CA | CS | CMA